The James Dyson Award has now given nearly £1m in prize money to over 250 promising inventions from young engineers and scientists in 28 countries around the world. In 2021, Sir James Dyson chose three global winners for the first time, each receiving £30,000 in prize money to support the next stages of their inventions.

Commenting on this year’s competition, Sir James Dyson said,

“I enjoy seeing the enthusiasm with which young people tackle the world’s problems using good design, engineering and science. So promising were this year’s entries that we’ve awarded a third prize, focused on medical invention. Commercialising an idea is very hard – I hope that the awareness that the Award drives, as well as the financial support it provides, will give these ideas a springboard to success.”

The winning inventions

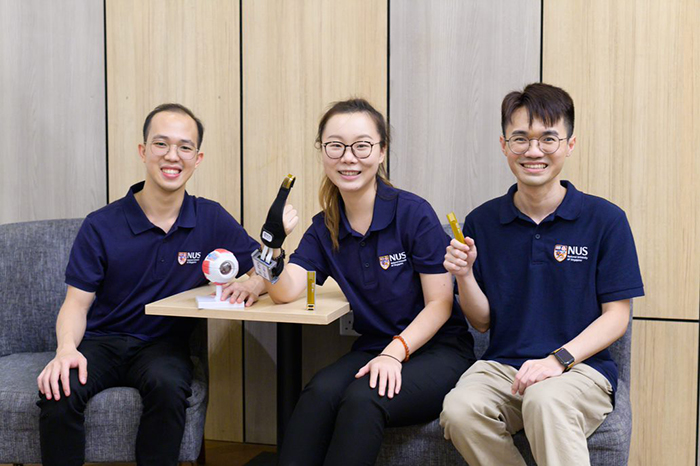

International winner – HOPES, designed by Kelu Yu, Si Li and David Lee

The problem

This year’s International winner of the James Dyson Award was inspired by one of the inventors’, Kelu, father’s diagnosis of glaucoma. After witnessing his discomfort and multiple hospital visits, she realised there is a global need for a less invasive and more accessible method for Intraocular Pressure (IOP) monitoring. Glaucoma is the second leading cause of blindness worldwide[1].

The International Agency for the Prevention of Blindness reports that in 2020, there were an estimated 2.9 million people with vision loss. Of these, 230,000 people were blind[2]. Glaucoma has been identified as one of the leading causes of blindness in the country where a recent study[3] reveals low awareness and knowledge levels about glaucoma among the attendees of a local eye care hospital, with several misconceptions about disease risk factors, clinical features, and management are identified. Because it is largely symptom-free, it’s also known as the “silent thief of sight”[4]. There is no cure but, if diagnosed and treated early, blindness can be prevented.

Today, regular IOP monitoring is a critical tool in helping clinicians determine long-term treatment plans and goals. This is achieved through the Goldmann Applanation Tonometry – regarded as the gold standard for the measurement of IOP. There is a demand for safe, accurate, low-cost, at-home IOP measurement devices to better improve the patient experience.

The solution

HOPES, (which stands for Home eye Pressure E-skin Sensor) is a wearable biomedical device for pain-free, low cost, at-home IOP testing. Powered by patent pending sensor technology and artificial intelligence, HOPES is a convenient device for users to frequently self-monitor IOP.

After creating a profile in the App, the user wears the HOPES glove with the sensor placed at the fingertip, pressing this against the centre of the eyelid. The fingertip employs a unique sensor architecture that captures dynamic pressure information of the user’s eye with sub-millisecond precision. The captured signals are processed by machine learning algorithms to continuously and accurately compute users’ IOP.

Data is transmitted via Bluetooth to paired devices or uploaded to the Cloud to be accessed remotely by clinicians. The App prompts users with easy-to-read measurement history and direct links to healthcare systems, allowing them to seek medical help to minimise future symptoms.

“I’ve experienced first-hand how invasive and unpleasant the tests for glaucoma can be, but it is a vital test. This group of young people have tackled a problem that doesn’t affect them directly, but which affects members of their family. Their work has the potential to make glaucoma testing much more widely available and I wish them every success as they navigate the challenging process of further development and medical approvals.” Sir James Dyson, Founder and Chief Engineer at Dyson.

Next steps

The team plan to collaborate with clinicians at the National University Hospital to collect and analyse patients’ eye pressure data to train the device’s machine learning mode. At the same time, they are working on optimising HOPES’ performance, and improving its design.

On winning the James Dyson Award International prize, the team say, “We were thrilled to hear from Sir James Dyson that we are this year’s International winners of the James Dyson Award. For us this all started with Kelu and her attempt to create a solution for her father after the problem they faced as a family. With this win, we hope in the future people can measure their eye pressure in a pain-free, at-home environment. We want to improve people’s quality of life and aspire to one day apply our research group’s sensor technology across different health monitoring applications, such as robotics and biomedical devices.”

Facts and stats

- Glaucoma is the second leading cause of blindness worldwide and IOP is currently its only modifiable risk factor.[5]

- The most common cause of blindness in Saudi Arabia is cataract, followed by diabetic retinopathy and glaucoma[6].

- In the past year, nearly 3 in 5 people have not had their eyes tested. Almost a third admit their last eye test was more than two years ago. 1 in 3 admit their eyesight got worse since the start of the pandemic.[7]

Sustainability winner – Plastic Scanner, invented by Jerry de Vos

The Plastic Scanner, invented by Industrial and Product Design graduate Jerry De Vos from the Netherlands, is this year’s Sustainability winner. Plastic Scanner is a handheld device that when held against plastic will tell the user what materials it’s made from, using infrared light to detect the plastic components.

The Plastic Scanner uses discrete infrared light to detect types of plastic – a new and low-cost approach to traditional infrared spectroscopy. The Scanner is also fully open-source hardware, so anyone can assemble the breakout board and embed the electronics into a handheld device. Open source welcomes feedback and improvements from experts, so the project will continuously improve as more people recycle plastic around the world.

“It may be fashionable to demonise plastic but it is a durable and versatile material which has an important role to play. The challenge, of course, is ensuring it is reused and recycled effectively to avoid it going to landfill. Understanding how to recycle plastics correctly is complicated but Jerry has developed a very effective technology that could put this knowledge into everyone’s hands.” James Dyson, Founder and Chief Engineer at Dyson.

Facts and stats

- Only 16% of plastic waste is recycled to make new plastics, with 40% sent to landfill, 25% to incineration and 19% is dumped[8].

- A study of consumers in the six member states of the Gulf Cooperation Council (GCC) found that more than 80% of those surveyed said they would be willing to adopt more sustainable lifestyles. However only around 10% of the plastic and metal waste that they produce is recycled, reused, or recovered, less than the global average of 32%.[9]

Medical winner – REACT, invented by Joseph Bentley

The REACT device (which stands for Rapid Emergency Actuating Tamponade) aims to reduce catastrophic blood loss from a knife wound. The current advice for treating stab wounds is to never remove the knife object from the wound if it is still in place[10]. This is because the object is applying internal pressure to the wound site whilst also filling the cavity and preventing internal bleeding. Joseph’s concept is based on the same principle, the implantable medical-grade silicone balloon tamponade would be inserted into the wound tract by a first responder. The actuator device is connected to the tamponade valve, and the user selects the wound location on the device interface. Squeezing the trigger on the actuator starts the automated inflation sequence, and the tamponade is inflated to a defined pressure based on the wound location to try and stem the bleeding.

“This type of problem solving invention shows the significant impact engineers can have on serious, global issues, and is why I created the James Dyson Award. Developing a medical device is very challenging and there will be no end of hurdles, but I would urge Joseph not to be put off since the opportunity to save lives is so great. I hope that through winning the Award this invention gets the support it requires as it has the potential to make an impactful change.” James Dyson, Founder and Chief Engineer at Dyson.

COMMENTS