The Electrical Engineering Division of the Saudi Council of Engineers, headed by Eng. Omar Al Shiekh, conducted a visit to the Desert Technologies PV Panel Factory in Jeddah affiliated with the Desert Technologies Group, one of the world’s leading companies in the field of renewable energy. They were accompanied by a delegation of students from the student branches of the Institute of Electrical and Electronics Engineers (IEEE) at King Abdulaziz University and Effat University.

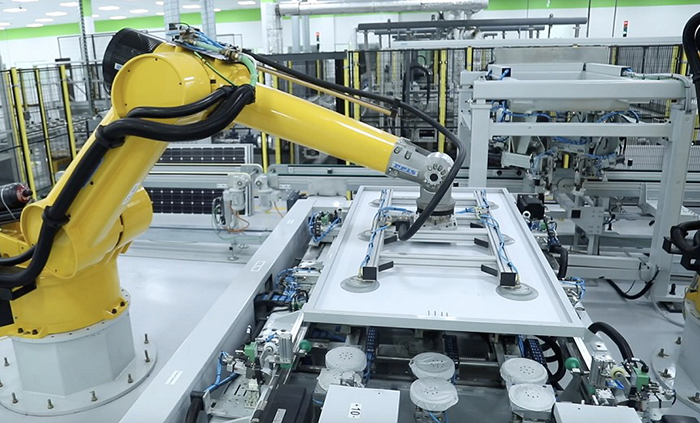

The director of the Desert Technologies Factory Eng. Muhammad Jamal Baaqil was at the reception of the delegation and gave a full explanation of the factory, which includes the newest production lines that keep pace with the latest global technologies. The visiting delegation toured the factory, viewing all the technologies used and manufacturing processes. Eng. Baaqil stated: “Desert Technologies Factory is the first and most advanced PV module manufacturer in the Kingdom of Saudi Arabia. Our state-of-the-art automated assembly line has a capacity of 110 MW. Our high-performance PV modules are fit for all utility, commercial, and residential projects dt’s Industrial Model is based on mono-PERC crystalline silicon, which is a proven and mature technology with a large room for future improvements. Our production line employs a sophisticated, fully automated manufacturing process supported by the most technologically advanced equipment from Germany, Switzerland and Finland. To maximize our output and ensure a high-quality product, we set up a tight control at each stage of the production.”

Baaqil confirmed that the plant’s production capacity is expected to reach 3 gigawatts in 2025, as the technology used in the plant is resilient, reliable and designed specifically for desert climates. High-efficiency PERC-monocrystalline 72-cells module achieves a power output up to 400 Wp and is Potential Induced Degradation – (PID) Resistant. The PV modules use High-quality, anti-reflection technology for higher yields, long-time stability and provide Long durability and high performance through tight and high-quality raw materials selection. All with a 12-year warranty on materials and workmanship and a 25-Year Linear Performance Warranty.

Eng. Baaqil said: “We are proud to be part of the national initiative launched by the Saudi Export Development Authority “Made in Saudi” Program, where our products that were exported and installed giant projects in many countries such as Mozambique, the UAE, Bahrain, Jordan, and Egypt represent an addition to our many local projects. We are proud of our product “Sahara” and its use in rural areas, military camps and other remote areas located outside the electrical network. “Sahara” containers represent a technical revolution in the photovoltaic power generation system in an easier and faster way in remote and difficult places which helps to provide a fertile environment for the establishment of many events.”

Eng. Omar Al Shiekh, Head of the Electrical Engineering Division, gave a brief presentation on the Saudi Council of Engineers, its objectives, most prominent achievements and statistics, and the benefits of membership for Saudi engineers.

He added that the renewable energy sector in the Kingdom is expected to provide many job opportunities as part of the broader goal of “Vision 2030”, as studies expect this sector to provide more than 750,000 jobs over the next decade. At the end of the visit, Eng. Omar Al Shiekh presented a memorial shield to Eng. Muhammad Baaqil, and Eng. Baaqil presented souvenirs to the members of the division bearing the signatures of the factory’s employees.

COMMENTS