Warwick Acoustics Ltd – a UK-based audio technology company, is working with a number of notable car manufacturers to support the elimination of Rare Earth Elements (REEs) from their vehicles thanks to its innovative ‘zero-REE’ ElectroAcoustic™ panels.

Warwick Acoustics CEO Mike Grant: “More and more enquiries are coming in from OEMs wishing to eliminate sources of REE from their vehicles due to the toxic waste generated in the mine-to-magnet process and supply chain stability. The big target has been permanent magnets in electric motors, with each motor containing roughly 500g of REEs. However, as much as 30% of the total REE content in a premium EV is actually in the audio system.”

“The extraction and processing of REE is unfortunately a process which generates a huge volume of waste per gram refined REE -– some sources suggest the amount of waste is 2000 times the amount of refined product. OEMs are keen to eliminate this legacy and at the same time remove any future issues with the very concentrated supply chain. When it comes to premium audio that is “rare earth free”, Warwick Acoustics has developed a unique “Clean Sound” solution for the industry, and this solution is capturing the attention of many premium OEMs.”

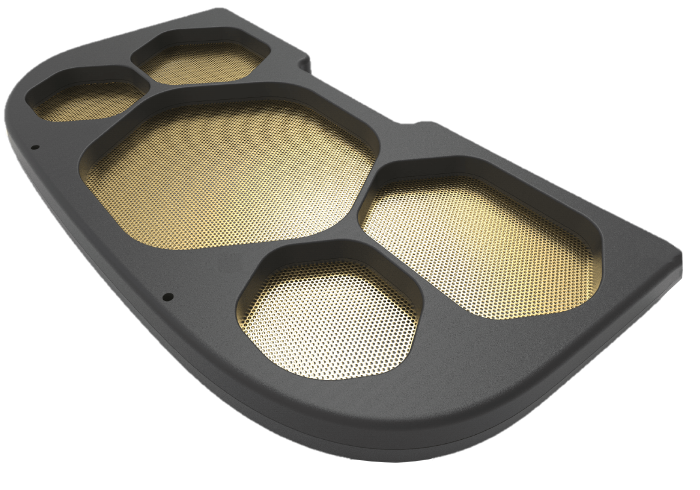

With seven granted patent families and two further patents pending, the British-designed and manufactured audio technology from Warwick Acoustics brings a revolution to in-car audio, moving away from the traditional format of a speaker, the fundamental principles of which haven’t altered since the first car radio was installed in the 1930’s.

ElectroAcoustic panels are lighter and thinner than any conventional speaker, without using any REEs, as Warwick Acoustic CTO, Ben Lisle explains: “Our technology is fundamentally different to a traditional automotive or home speaker. By eliminating the magnet and replacing it with a 1mm thin electrostatic panel, we are able to offer a loudspeaker which is up to 90% lighter and more efficient than a like-for-like moving coil speaker.

“Our technology doesn’t just eliminate REE content. We also use ‘100% by mass’ upcycled and easily recyclable materials in the manufacturing process to produce a final product that is highly sustainable, and, given its very simple design, easy to disassemble at end of life.

“Importantly, Clean Sound doesn’t come at the expense of performance. Our technology delivers the highest levels of acoustic fidelity, and, as demonstrated in our award-winning headphone systems, is impressing the most discerning of audiophiles.”

Warwick Acoustics’ ElectroAcoustic Panels are now in the final phases of industrialisation for the first customers of this new proprietary technology – perfectly timed to meet automotive OEMs’ rapid transitions to electrification and life cycle sustainability.

COMMENTS